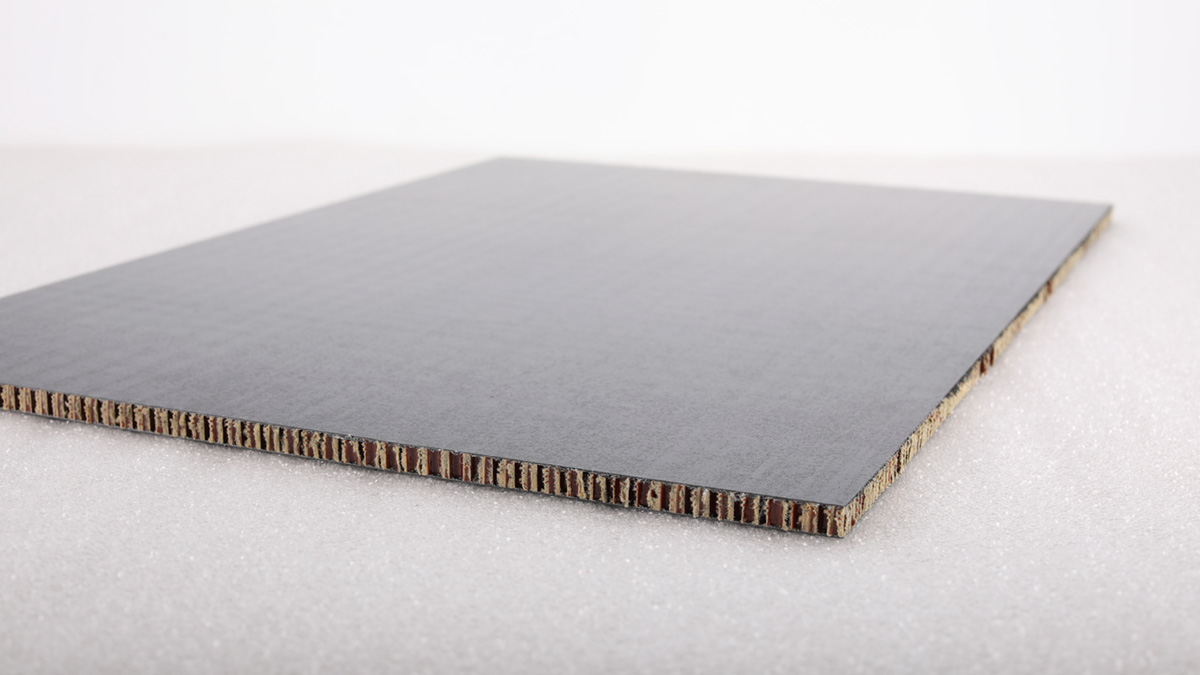

Sandwich Panels

JCB Aero produces its own sandwich panels including a choice of Honeycomb, Aluminium or foam core with Glass, Carbon, Aluminium, Kevlar, or a mix of e-Glass and Carbon Fiber Skin, along with a choice of Phenolic or Epoxy Resin.

The standard panel thicknesses available are 0.125, 0.190, 0.250, 0.375, 0.500, 0.750 and 1.000 [inch], with a standard dimension of 2’400mm x 1’220mm with a maximum size of 3’600mm x 1’500mm. However, different thickness can be manufactured upon demand thanks to the efficient and high performing slicing machine. Panels can be customized as requested (edge filling, metal inserts, Tedlar, etc.)

With its own in-house ‘A & B’ value testing facility, all panels are tested and approved at JCB Aero.

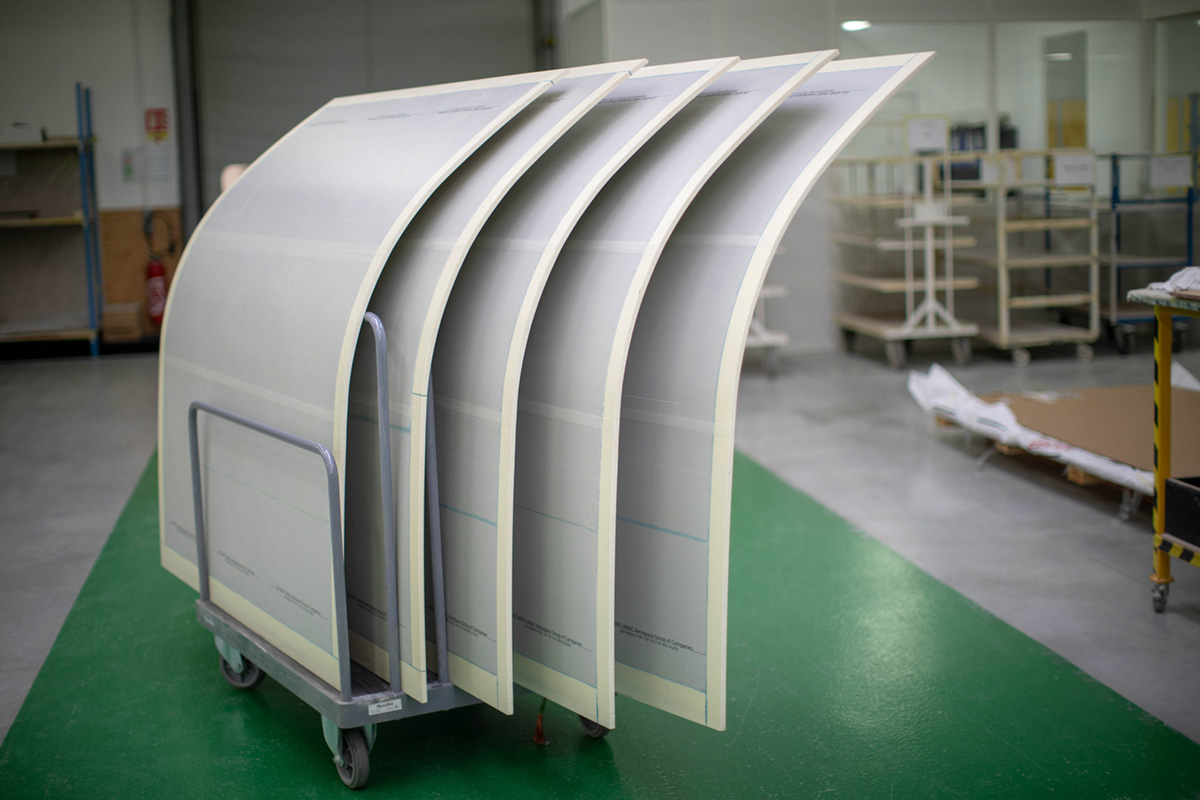

Floorboard Panels

JCB Aero has developed a floorboard panel, compliant BMS4-17/20/23, for the MRO market. These panels offer a substantial weight gain and can be install on 95% of Boeing Cabins. Lead-times experienced from JCB’s production process has been reduced significantly compared to OEM floorboard production. JCB Aero offer the capability to deliver customized floorboards with multiple STC’s.

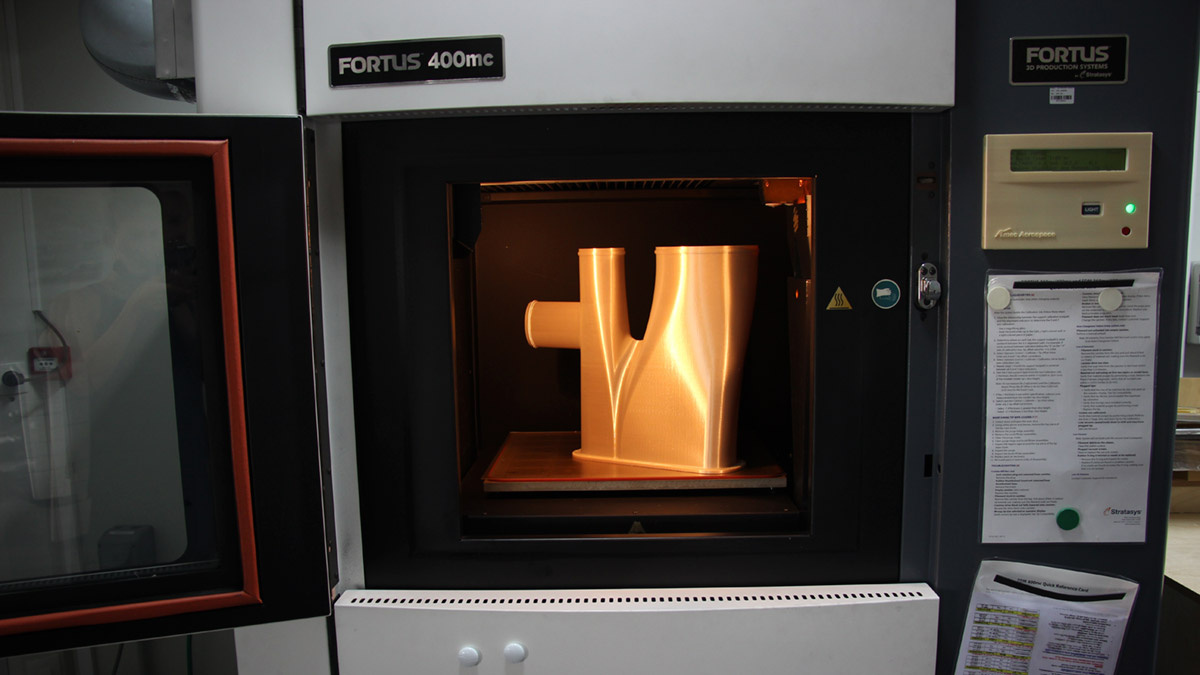

New Technologies

JCB Aero are equipped with the latest generation tool as HandySCAN 3D, to map parts (shape, dimension and volume) therefore allowing their engineers to register customized and standard components on aircraft. JCB Aero have capabilities to ensure and qualify parts in Ultem 9038. JCB has also implemented and exercised daily the new ‘Manufacturing 4.0’. It works by digitalizing all manufacturing orders, which is delivered via a means of a ‘MES’ and therefore increases productivity and JCB’s overall capabilities.

JCB Aero